415 Union Street · Sebewaing, Michigan 48759 · Phone: (989) 883-2000

Mixers

Devolatilization processes are often a key issue in the production of high-quality polymer products. With legislation and stricter environmental requirements demanding lower residual organic volatiles in plastic materials, efficient devolatilization is mandatory for any modern polymer production plant.

After polymerization, the product usually still contains significant amounts of unreacted monomers, oligomers, solvents, and other impurities. Some of these remaining chemicals are harmful or react with the polymer chains during later processing, making their removal an important step to obtain a commercially usable polymer.

The removal of volatiles from polymer melts is a complicated task not only because diffusion from the polymer is strongly limited by viscosity. Solvents and monomers often also exhibit rather high boiling points, making it more difficult to evaporate them at temperatures that do not harm the polymeric matrix.

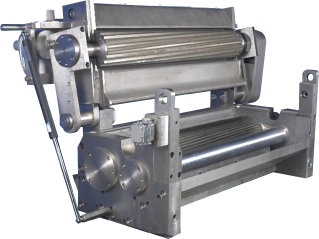

Devolatization Mixers

Polymer devolatilization technology (Post Devolatization Mixers for polyetheline or clear plastic – static or pin). Sebewaing Tool and Engineering can make the mixer you require, to your exact specifications and requirements.

Sebewaing Tool and Engineering has long been a supplier of Pumps, Mixers, Granulators, Strand Die Assemblies, etc. to the plastics processing industry. We specialize in large capacity equipment built to our own or proprietary customer designs. All components are manufactured, assembled and tested in-house.

We're Here To Make Your Life Easier.

reverse engineering

call

989-883-2000

ext. 119

pump solutions

call

989-883-2000

ext. 122

valve hardware

call

989-883-2000

ext. 123