415 Union Street · Sebewaing, Michigan 48759 · Phone: (989) 883-2000

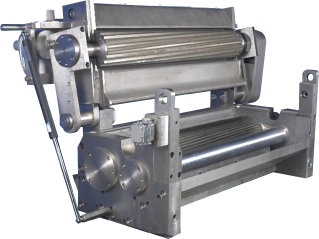

Brackets and Mounts

Sebewaing Tool and Engineering has been a supplier of valve automation hardware and accessories since 1975. We are a top supplier of flow control hardware, kits, and supplies to the chemical/petrochemical, water/wastewater, gas, oil and food industries.

Premium Brackets and Mounts

Due to the high failure rate of “commodity” brackets, mounts, and couplings that are usually included with valve automation kits, Sebewaing Tool and Engineering has developed our own line of premium brackets, mounts, and couplings engineered by us to maximize valve/actuator life-cycle, and minimize costly repair, maintenance, and replacement. Think of Sebewaing for longer lasting flow control equipment, supplies, and hardware, or ask us about our expert engineering of your flow-control system.

Hardware for Brackets and Mounts

NOTES:

Order processing cannot begin until all relevant information and drawings, if required, are obtained by Sebewaing Tool and Engineering Company from our customer, the manufacturer or the end user.

Bracketry may be tubing or formed based on the application. Sebewaing Tool and Engineering reserves the right to use methods developed by our engineering department unless otherwise specified by our customer.

ISO and NAMUR mounting provisions may allow for direct drive of some components, omitting the need for a drive coupling. A price reduction may result.

Standard carbon steel linkages consist of an enamel painted bracket and coupling with all required Grade 5 zinc plated fasteners. Epoxy coating is also available. Stainless steel kits consist of a 304SS bracket, 303SS coupling and all required 18-8SS fasteners. Hex head cap screws are typically supplied. However, Sebewaing Tool and Engineering Company reserves the right to supply fastener style based on design criteria.

Additional charges may apply for materials other than those noted.

Additional charges required for: stud mountings, packing gland adaptations, cradle brackets, jacketed valves, sleeved couplings, two piece split couplings and couplings with set screws, heavy duty brackets (3/8" wall and above) and special bracket height requests. Quantity discounts are based on quantities of the same kit.

Project pricing available. Please note: any add-ons to a project purchase order, after the hardware has entered production, will be reviewed and may be repriced based on the quantity.

For applications involving torque values above 17,000 in. lbs, consult Sebewaing Tool and Engineering for heavy duty kit pricing.

Blanket order pricing is available. Inquire with your particular requirement. All purchase orders will be confirmed via return fax, e-mail or phone call. Stock items can ship 1-2 working days after receipt of order; ship date to be determined at the time of order.

Engineering Design For Brackets and Mounts

Bracket material thickness - varies with the specific process requirements. Below are commonly used material thicknesses for various valve types and sizes.

- Type of Valve Size Thickness

- Butterfly 2" - 6" 3/16" (.19")

- Butterfly 8" - 12" 1/4" (.25")

- Ball and Plug 1/4" - 1" 1/8" - 3/16" (.13" - .19")

- Ball and Plug 1" - 2" 3/16" (.19")

- Ball and Plug 3" - 6" 1/4" (.25")

- Bolt clearance holes are 1/16" (.06") larger than the nominal bolt diameter

- Formed brackets have a height tolerance of +.03"/ -.02". Height tolerance for tubing brackets is standard tube stock tolerance

- Mounting hole pattern tolerances are held to +/- .015"

- Coupling drive tolerance is +.002"/.005" above the published valve stem dimension

- Coupling length tolerance is +.005"/-.02"

Materials

The thickness of the material used for mounting brackets is determined by the size of the valve, actuator and torque requirements. 1/8" to 3/8" thick material is used for formed brackets.

Applications requiring thicker material will either be fabricated or supplied as tubing. Tensile strength for carbon steel brackets is 58/80,000 psi.

Stainless steel material for standard brackets is 304-SS with a tensile strength of 100,000 psi. 316-SS material is also available.

Stainless steel couplings are made from 303-SS stock with a tensile strength of 85/120,000 psi. 17-4 SS and 316-SS are also available.

Valve Mounting Hardware

- Stainless and exotic materials

- Override and gear operator mountings

- Manually operated switch assemblies

- Enclosed pocket drive couplings

- Valve to actuator linkages

- Positioner and switch kits

- Iso coupling blanks

- Dow spec linkages

- Stem extensions

- Iso and namur

- Brackets only

- Tandem kits

- Lockouts

We're Here To Make Your Life Easier.

reverse engineering

call

989-883-2000

ext. 119

pump solutions

call

989-883-2000

ext. 122

valve hardware

call

989-883-2000

ext. 123